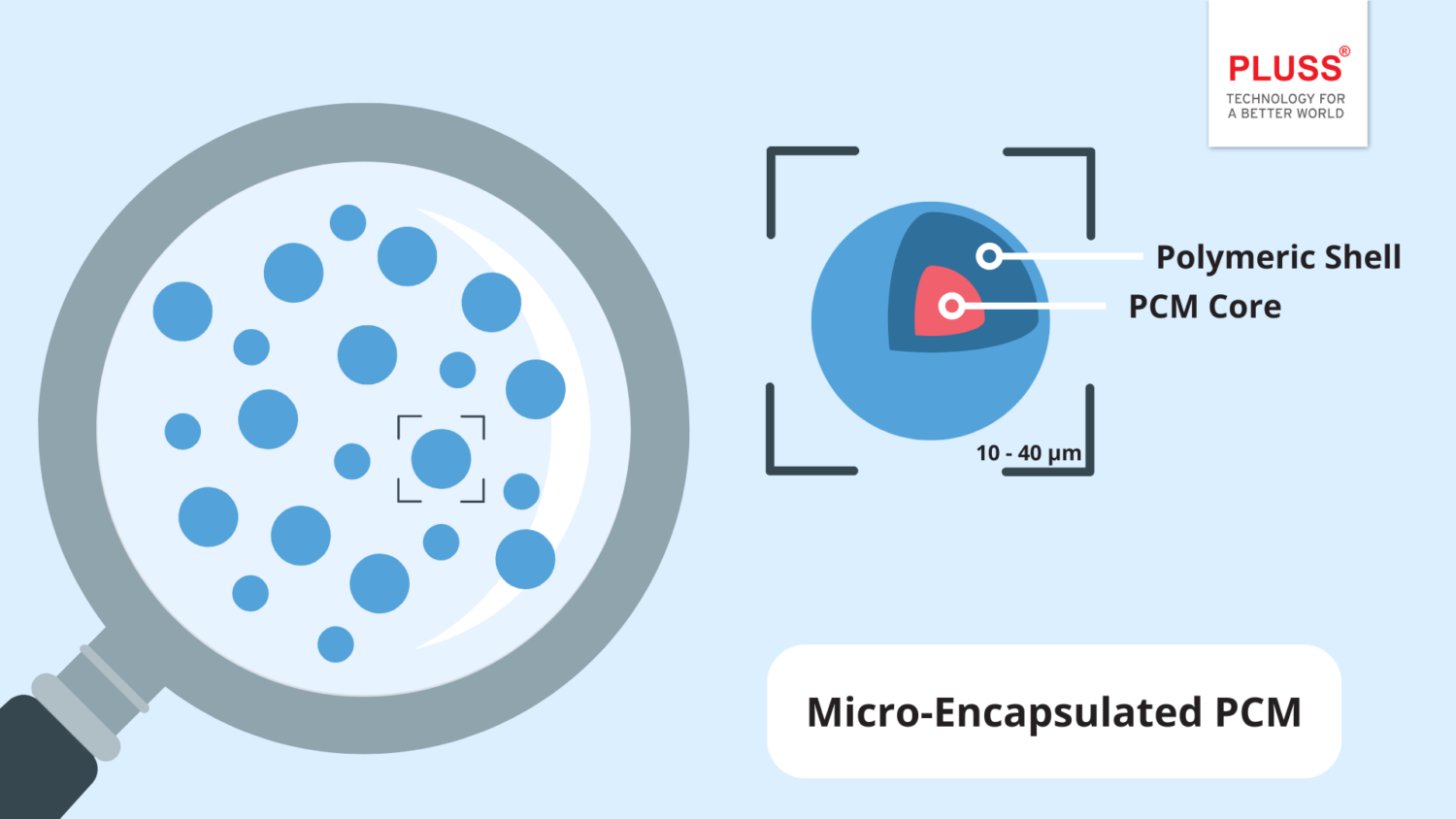

What are Micro-Encapsulated PCM?

Micro PCM, short for Micro-Encapsulated Phase Change Materials, are innovative substances engineered at a microscopic scale. These materials possess the ability to store and release significant amounts of energy during phase transitions, making them invaluable across various industries. Micro PCM are typically composed of a core PCM material surrounded by a protective shell, often made of a polymer or other encapsulating material. In terms of its forms, Micro PCM can exist in different compositions: it can be water-based, consisting of 60% water and 40% PCM, or slurry-based, consisting of 60% PCM and 40% shell material. They offer enhanced thermal stability and versatility compared to traditional PCM materials.

Applications of Micro PCM

From construction to electronics, Micro PCM finds diverse applications:

Building and Construction: Micro PCM integrated into building materials like concrete, plaster, or insulation can regulate indoor temperatures, reducing the reliance on heating and cooling systems and enhancing energy efficiency.

Textiles: Incorporating micro PCM into fabrics enables the development of clothing that adapts to environmental conditions, providing thermal comfort in both hot and cold climates.

Electronics: maintaining optimal operating temperatures is critical, requiring efficient thermal management. Micro PCMs, acting as TIM (thermal interface material), enhance thermal coupling between components like integrated circuits and heat sinks by dissipating heat effectively. Applied as coatings, these micro PCMs prevent electronic components from overheating.

Matrasses: When infused with Micro PCM, these mattresses can offer a solution to regulate body temperature during sleep, promoting a comfortable and restful night’s rest. By actively managing heat exchange, these innovative mattresses create an optimal sleep environment, helping individuals achieve deeper and more rejuvenating sleep experiences.

Real-Life Examples

Micronal® by BASF: their own Mirco PCM is made from paraffin granules encapsulated in a polymer, Micronal® microcapsules are around 5 micrometers in diameter. They can be added to materials like plasterboard, plasterwork, and concrete. They have a melting energy of 100kJ/kg and a melting temperature of 23°C.

Comfortboard by Knauf: they designed a plasterboard with a micro PCM thermal mass lining, storing and releasing latent heat. It ensures comfortable indoor temperatures, reduces heating and cooling costs, and saves space and construction time compared to traditional options.”

Limitations

While micro PCMs offer numerous advantages, they also come with limitations:

Cost: The production of micro PCMs involves intricate processes such as micro-encapsulation, which can contribute to higher costs compared to traditional PCM materials in macro-encapsulations.

Material Compatibility: The selection of matrix materials for micro-encapsulation is crucial to ensure compatibility with specific applications and environments.

Thermal Conductivity: Some micro PCMs may exhibit lower thermal conductivity compared to traditional materials, which could affect their effectiveness in certain applications requiring rapid heat transfer.

Our Temperature Range

Our ongoing research and development focus on Micro PCM has yet to reach the stage of commercialization. However, we have identified several potential temperatures ranges suitable for our Micro PCM, including 4-5°C, 15-18°C, and 30-40°C. If you’re interested in delving deeper into our Micro PCM and exploring potential collaboration opportunities in its development, feel free to contact us. We’re enthusiastic about engaging with interested parties to further our research and innovation efforts.