Harnessing the Power of Phase Change Materials: Unlocking Sustainable Solutions

In the pursuit of sustainable and energy-efficient technologies, researchers and engineers are exploring innovative solutions to decrease energy consumption and address environmental impact. A notable breakthrough in this endeavor involves Phase Change Materials (PCMs). These remarkable substances possess the capability to store and release thermal energy during phase transitions, providing distinct advantages in applications such as pharma logistics and building design. This article delves into the concept of PCMs, distinguishes between sensible heat and latent heat, explores their applications in pharmaceutical logistics and buildings, and underscores the six key benefits of PCMs in fostering a more sustainable future.

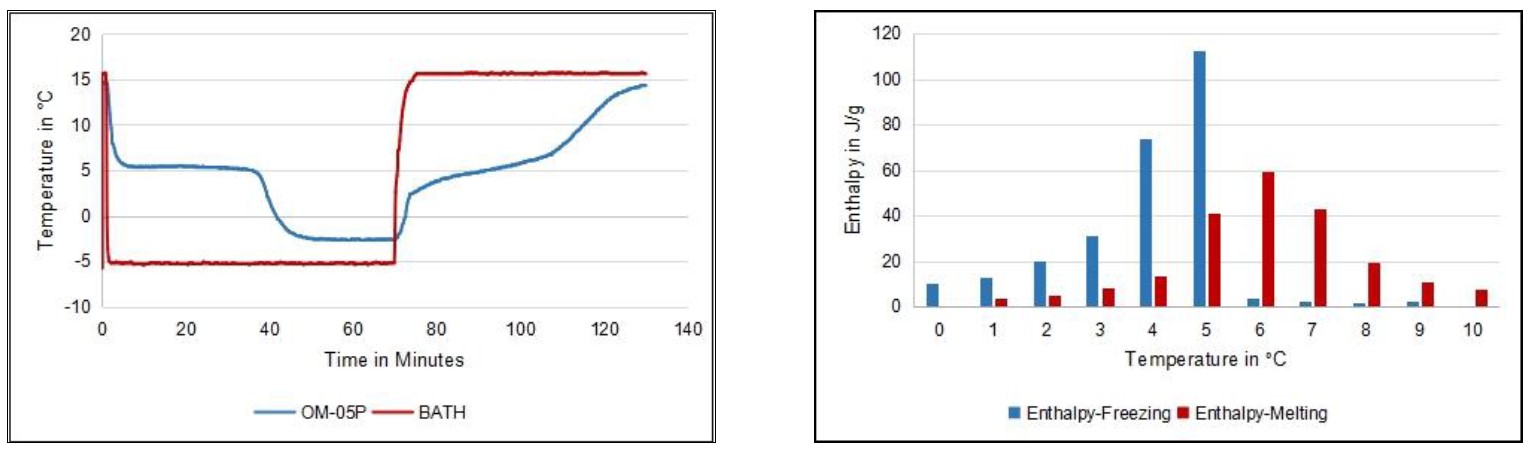

Phase Transition Temperature Range & Stored Thermal Energy of OM05-P

Understanding Sensible Heat and Latent Heat:

To comprehend the significance of PCMs, it’s vital to discern the difference between sensible heat and latent heat. Sensible heat involves energy transfer causing a temperature change without a phase change. Applying or removing heat from a substance leads to a linear temperature rise or fall. In contrast, latent heat is linked to a phase change, like the transformation from solid to liquid or liquid to gas. Throughout these transitions, temperature stays constant as energy is absorbed or released. This distinctive aspect of latent heat is the key factor that renders PCMs highly valuable in diverse applications.

Applications in Pharma Logistics

Maintaining the integrity of temperature-sensitive pharmaceuticals during storage and transportation is of utmost importance. PCMs is used globally as a reliable solution by ensuring that medicines and vaccines are kept within the required temperature range. For example, PCM coolants can be used in insulated shipping containers and boxes to maintain a consistent temperature, preventing heat spikes or drops that could compromise the efficacy of these vital products. By utilizing PCMs, pharmaceutical companies can ensure the potency and safety of their products, reducing the risk of waste and minimizing the environmental impact associated with temperature-controlled logistics.

Applications in Buildings

Buildings account for a substantial portion of global energy consumption. By incorporating PCMs into building design, we can significantly reduce the energy required for heating and cooling. PCMs can be integrated into walls, floors, and ceilings to store excess heat during the day and release it at night when temperatures drop. This passive thermal regulation minimizes the need for mechanical heating and cooling systems, thus reducing energy consumption and carbon emissions. Additionally, PCMs can be used in active cooling systems, such as air conditioning, to enhance energy efficiency and optimize occupant comfort.

Benefits of PCMs for a Sustainable Future

Energy Efficiency: PCMs enable energy savings by reducing the reliance on traditional heating and cooling systems, thereby decreasing carbon emissions and mitigating climate change.

Reduced Waste: In pharma logistics, PCMs help maintain stable temperatures, minimizing product spoilage and waste, resulting in more efficient supply chains and reduced environmental impact.

Renewable Integration: PCMs can be derived from renewable sources, aligning with the shift towards sustainable materials and reducing dependency on finite resources.

Improved Comfort: By regulating temperatures effectively, PCMs enhance occupant comfort, reducing the need for excessive heating or cooling and promoting energy-efficient building designs.

Enhanced Thermal Storage: PCMs can store thermal energy from renewable sources, such as solar and wind, for later use, enabling better integration of intermittent energy generation into the grid.

Longevity and Durability: PCMs have excellent thermal stability and can withstand numerous phase change cycles, ensuring long-lasting performance and minimizing material replacement.

Conclusion

Phase Change Materials present a revolutionary approach to energy management, carrying substantial implications for various sectors. Leveraging the latent heat properties of PCMs allows us to enhance energy efficiency, elevate product preservation, and diminish environmental impact. The incorporation of PCMs in pharmaceutical logistics and building design exemplifies their capacity to transform industries and foster a sustainable future. As we persist in exploring and advancing the utilization of PCMs, we edge closer to realizing a greener and more efficient world.